Comprehensive analysis of in / on-cell / OGS scree

Category:Company news Source:Hongjia United Views:3406 Date:2016/1/5As for the hype about the screen concept, from the previous panel dispute among IPS, AMOLED and SLCD to now all advertised that they are OGS full fit screens. Apple seems to be more "high-end" and spread the concept of in cell / on cell. Cook this issue of popular science about OGS / in cell / on cell screen, strive to be easy to understand, and hope to let everyone know the truth in the simplest way.

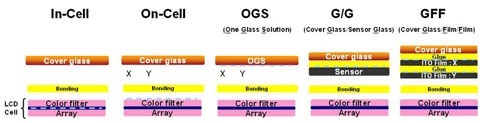

To thoroughly understand in cell / on cell / OGS and other screens, you must first know the basic structure of the screen.

From top to bottom, the basic structure of the screen is divided into three layers: protective glass (the top orange yellow indicates the part of cover glass), touch layer (a little light blue dotted line in the figure indicates the parts of X and y), and display panel.

There's nothing to say about protecting glass. Corning gorilla glass is. The touch layer is composed of ITO touch film and ITO glass substrate. The display panel can be subdivided to a high degree, which is only roughly arranged from top to bottom, They are the upper glass substrate (the area marked with color filter in pink, that is, the color filter substrate), the liquid crystal layer (blue bar), and the lower glass substrate (the area marked with array in pink, that is, the thin film transistor substrate). Finally, it should also be pointed out that a layer of air will be formed between the protective glass / touch layer and the display panel (that is, the golden area of bonding is marked in the figure). If the full bonding technology is used to remove this layer of air, the reflection of the screen will be greatly reduced. When the screen is lit, it will be more transparent, and when the screen is turned off, it will be more dark and gray.

The traditional g / g and GFF screens are standard protective glass + touch layer + display panel layer. The difference is the touch layer. The touch layer of g / g screen is composed of 1 ITO glass substrate + 1 ITO touch film, while the touch layer of GFF screen has 2 ITO glass substrates + 2 ITO touch films (ITO: X and ITO: y). Obviously, g / g screen is thinner.

Today, the OGS screen and in cell / on cell screen advertised by various manufacturers are worth boasting because they are the structure of protective glass layer + display panel layer, which is lighter and thinner without a touch layer. Where's the middle touch layer? This is the key to distinguish between in cell / on cell screen and OGS screen. The in cell / on cell screen integrates the touch layer and the display panel, and the OGS screen integrates the protective glass layer and the touch layer. In order to compete for the right to speak in the industry, touch module manufacturers push OGS, while display panel manufacturers such as LG, Samsung and sharp push in cell / on cell.

Some people may find out that since both the in cell screen and the on cell screen integrate the touch layer and the display panel, how to distinguish between in cell and on cell? This is related to the position where the ITO film is embedded in the display panel. The so-called on cell is to place the ITO touch film on the upper glass substrate of the display panel, which is what several generations of Samsung Galaxy flagship do; As for in cell, the ITO touch film is placed under the upper glass substrate of the display panel, which is generally integrated with the liquid crystal layer. The representative model is Apple's iPhone 5.

1. In terms of screen permeability and visual effect, OGS is the best, followed by in cell and on cell. So, it's time to brag about how transparent the in cell / on cell is and how good the visual effect is. Whether it is the iPhone 5 or the Samsung Galaxy S4, the simple screen permeability is actually not as good as some domestic mobile phones with OGS screens, such as Meizu MX3.

2. Lightness. Generally speaking, in cell is the lightest and thinnest, which is one of the reasons why the iPhone can be extremely light and thin with a metal body. OGS is the second, and on cell is slightly worse than the first two.

3. Screen strength (impact resistance and fall resistance), on cell is the best, OGS is the second, and in cell is the worst. It should be pointed out that OGS directly integrates Corning protective glass with the touch layer, which weakens the strength of the glass during the processing, and the screen is also very fragile. As for why the strength of the in cell screen is poor, I don't know the reason. This may be the same as Apple's own in cell In terms of lightness and thinness, lumia 920 is also an in cell screen, but it has good auxiliary design / measures to enhance the impact and fall resistance of the screen. In addition, it should be pointed out that because in cell integrates the touch layer with the liquid crystal layer, once the touch screen has a problem, it needs to be replaced together with the display panel.

4. In terms of touch control, the touch sensitivity of OGS is better than that of on cell / in cell screens, but sometimes this is not a good thing. OGS technology does not pass the test, and the ultra-high sensitivity is prone to "screen skipping". Fine dust, sweat and water vapor can cause "misoperation" of the touch screen. For example, the problem of the first batch of MX3 machines is more serious. In fact, OGS is better than in cell / on cell in terms of support for multi touch, finger and stylus. In addition, because the in cell screen directly integrates the touch layer and the liquid crystal layer, the sensing noise is large, and a special touch chip is required for filtering and correction. The dependence of OGS screen on touch chip is not so high.

5. Technical requirements: in cell / on cell are more complex than OGS, and production control is more difficult.

6. In terms of yield rate, the yield rate of in cell screen was low before, which greatly affected the supply of iPhone 5 and other products. However, with the continuous investment of manufacturers and the maturity of technology, the yield rate of in cell / on cell screen is at the same level as OGS, and large-scale shipment is not a problem.